Weekend Update: Saturday 1/21 & Sunday 1/22:

Progress is moving forward, this past weekend was about three systems:

-Fuel & Intake

-Alternator & ECU

-Driveshaft

Happy to report that I got them mostly checked off the list with a few straggling items, but those are easy enough to pick up along the way (just have to make a note of them and not forget them).

FUEL SYSTEM:

I had already installed the three 8x13 Fuel Hoses (Supply, Return and Vapor Canister) coming up through the Driver’s Wheel Well before the engine went in. So the real items to install were the Fuel Rail, Fuel Pressure Regulator Valve and Fuel Injectors; then it was a matter of connecting the Supply & Return Hoses to Rail and FPR and securing them in the engine bay.

Since I have eliminated the Charcoal Canister from the Vapor Recovery System (in all honesty it wasn’t even attached or hasn’t been for some time), I will just terminate the Hose here in the engine bay. I’ll cut it short (+/-6”), turn it down and secure it off the fender. If I ever have to install it again, it is a simple connection and re-installation of a Canister.

I have also decided to return the FPR to the original stock Bosch 3.0 unit in lieu of re-installing the previous BMP Adjustable Fuel Regulator Valve. I had countless people ask me what the advantage of it was over the fixed Bosch unit and I honestly couldn’t come up with an answer. I’m sure there is one (or was one when it was originally installed), I just don’t know it; I’m sure someone out there can shed some light on it. [I don’t think I have promised it to anyone so the BMP is up for sale]

ELECTRICAL: ALTERNATOR & ECU

ELECTRICAL: ALTERNATOR & ECU

Ralph and I worked on getting the last of the Johnson Box and its’ wiring removed from the ECU Connector and Main Harness. Turned out it wasn’t as bad as we first assumed; there was only one wire they cut and spliced into, the rest of the wires from the J-Box were piggy-backed into the ECU connector slots. Ralph meticulously removed them (I knew buying that Terminal Pick kit was the right move) and then handed me the former J-Box wire harness like some screaming alien. Simple repairs to the existing Main Harness wiring, re-taping it all and we can button the whole connector back up and reinstall the ECU and put the Glove Box area back together. Before:

After:

Alternator:

Alternator:

With that handled, I put the Alternator on the bench for some cosmetic touches. I had some parts off of a donor plated (fan wheel and some washer/spacers) so I swapped those out with those that came with the remanufactured 130A unit. Also gave it a quick layer of clear coat heat resistant enamel.

This is a later model AL-140X with the non-bushed mounts that matched the later Alternator Bracket. The later models do not require a separate ground strap wire as the unit is essentially grounded through the bracket and mounting bolts. This unit also utilizes the later U-shaped Adjusting Bracket instead of the single front bar type on the older units. This change should result in more stability and easier adjustments.

All that is left is to do the electrical connections and final adjustments after we get the pulleys and belts installed.

DRIVESHAFT:

All the missing components for the Driveshaft rebuild came in last week so Ralph and I embarked on putting it back together and installed into the car. The big push here is so I can get the car back down on the ground so we can final torque the Crank Hub Nut (Jesus Nut) and then get the Cooling System installed.

Not too many pictures here since both Ralph and I had our hands full wrestling the Dust Shields and Center Bearing into place. Suffice it to say, it all goes back together reverse of removal. The hardest part, which should have been the easiest, was getting the first Dust Shield squarely seated on the Spindle Shaft. Had we had a pipe that was the correct diameter to marry to the lip of the Shield, it would have been easier; but alas we did not so it was a struggle. It also put up a fight on the last ½” so we had to find a way to really drive it on without totally destroying it at the same time.

Once that was achieved we got the rest of the Center Bearing (cover & mount bracket) and other components installed. I re-painted the rest of the Driveshaft last week so it was ready for installation:

Installation:

Installation:

With that done, we hopped under the car and lined up the Shaft for installation. Here is where we discovered that Jim Blanton likely forgot to install the three M10x55 bolts that face rearward to bolt into the Guibo on the back of the Transmission. Ralph refused to do what had been done previously and install all six bolts facing the front of the car. After some frustrating attempts at trying to slip those long bolts through the holes between the Input Shaft and Transmission case (futile), we then had to loosen the 30mm rear mounting nut on the Input Shaft to move that bracket out. That took a bit of work that only was achieved through pneumatics. Upside was I got to use both the Sanborn Compressor and my new Aircat 1150; nice combo that made short work of that nut.

Now with those three in the correct orientation, we were back in business and got the shaft mounted front and back (Transmission and Differential). Realizing we didn’t have the correct thread pitched M10 hardened lock nuts, we had to forgo the final torque and Center Mount locking and setting in place. [Those nuts just arrived in today’s mail so we are good for Saturday for this procedure.]

GEAR SHIFT RE-VISITED:

I didn’t do anything here to what we did previously, only I realized that I had not taken any pictures of the Z3 Gear Shifter and Linkage installed. Thought I would take a few pictures of it before the DS gets finalized and the Heat Shield gets installed covering to the whole Magilla:

Ralph said I should mention that one critical upgrade everyone should do regarding Gear Shifters is to replace the stock older E28 Linkage (Gearshift Rod Joint in BMW parlance) with a newer E46 version. Someone had done this more recently in the cars’ past before I got it since this Transmission and Shift Kit went in around 1994 (unless this is an E36 unit?): Here are some examples for illustration:

The newer unit has a solid body instead of the weaker smaller shaft style of the older one; the old ones were prone to shear off at the junction. Good upgrade.

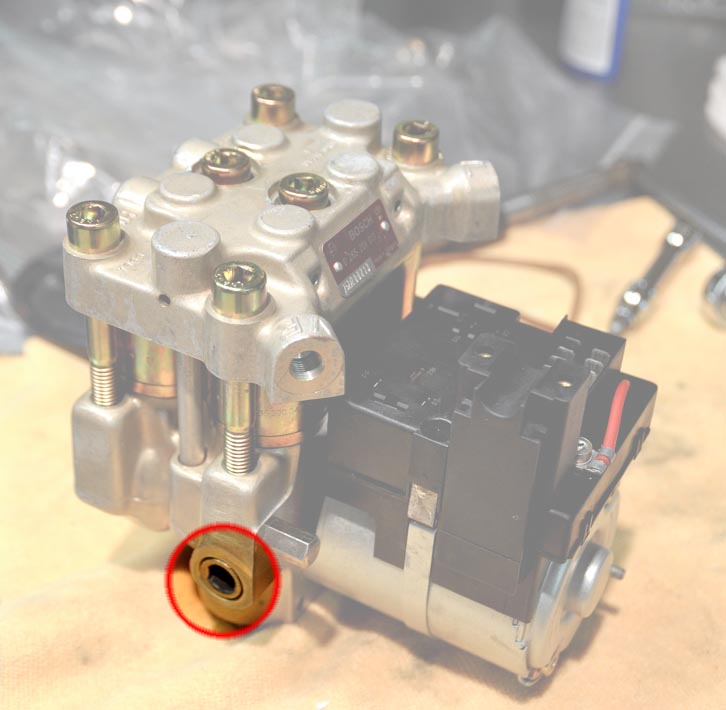

HYDRAULIC SYSTEM RE-VISITED:

Specifically the Fluid Cooling Loop. I said I would return with some pictures of it installed so here you go:

Well, that was this weekend. Next weekend is A/C System and removing the exterior Door Trim so I can run them down to be refinished at Speedway next week.