Well, I just placed the orders with SDP-SI and McMaster Carr. The force feedback wheel should become a reality inside the next few weeks.

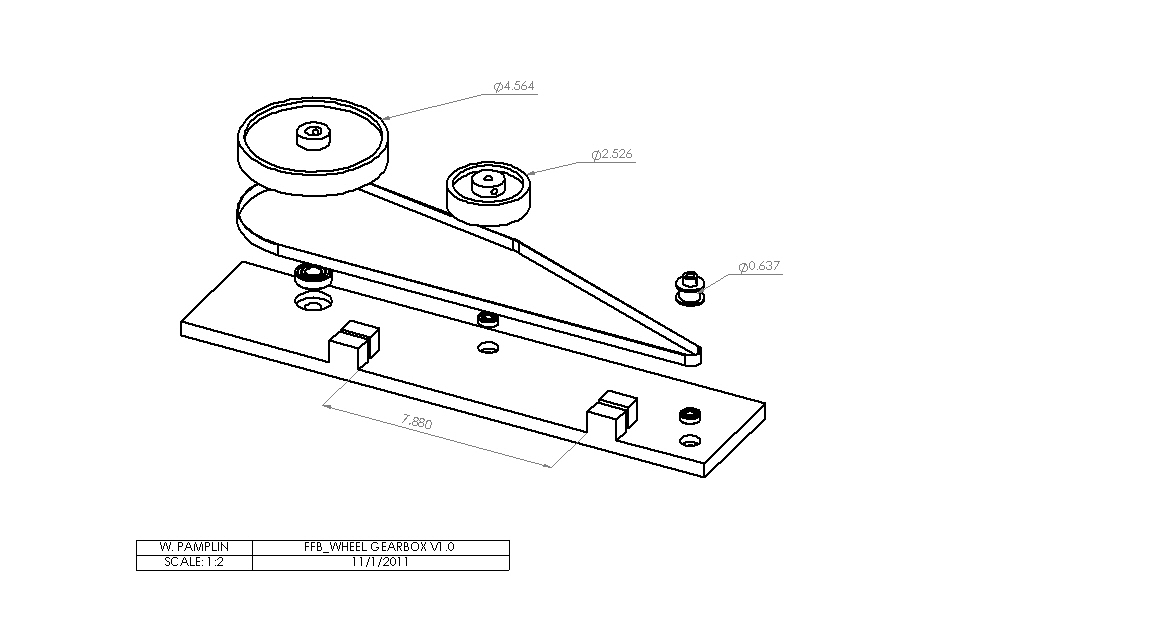

The pic above is a Solidworks rendering of it. I built the models of the gears based on dimensions from the SDP-SI catalogs. They are actually 0.200" pitch (XL) timing belt gears, I just didn't model the teeth. Also missing from the rendering are the shafts, top plate (and bearings), and the wiper motor to power the whole thing.

The small gear on the right is a 10 tooth for the input shaft (from the steering column), the middle gear is a 40 tooth for the potentiometer to measure position, and the far left gear is a 72 tooth for the windshield wiper motor to mount to. The small blocks at the bottom of the plate are stops for a

clamp which will mount to the belt. When the clamp hits the blocks, it will stop the whole system from rotating. If I did the math right it should facilitate 3 turns from lock to lock. The 4:1 reduction to the potentiometer gear allows for 270° of rotation, so that I can use most commonly available pots. The last gear is at a huge 7.2:1 reduction to counteract some of the gearing on the wiper motor. This will mean that the wiper motor will only turn ~180°, which is just fine. It's more for delivering vibrations, impacts, and steering feel, so resolution isn't terribly important. The main thing I want to convey through the wheel is that threshold of grip just before catastrophic understeer takes over. I will be implementing a weak, speed-dependent centering algorithm.

The plate itself will be made from 1/2" thick high density polyethylene, as are the blocks.

Soon to come: the I/O board and the H-Bridge

This thing should beat the hell out of any off the shelf racing wheel (and cost less to boot)