|

|

|

Some suggestions on where

to look on your 528e if

you

have electrical or running problems, based on the kind

of typical problems I've seen with my 528e and others.

(click the date link to go to the update location)

|

|

Before you start... Make sure you have a copy of the BMW E28 factory Electronic Troubleshooting Manual (ETM) for your model year

E28. They are available here in .pdf format. Scroll down the page to the "Electronics" heading.

Another ETM location has been found here, which has no relationship to being a BMW support site, so its

the only BMW material present. Second, download a copy of my text listing of what electrical ground point is associated with what

device, to help you troubleshoot ground fault problems. Without these two documents, you'll be stumbling around in the dark.

Stalling, won't start, or suspected fuel pump

problem.

Make sure Fuse #1 is not blown, or has trouble making good

contact due to corrosion or weak fuse holder arm retainers. Replace the fuse or check for continuity at the base of the fuse

holder arms, not at the top where the process of checking may cause a bad connection with the contact arm retainers to make

intermittent contact, causing you to think the fuse holder is OK, when it may not be. DO NOT REPLACE

FUSES WITH FUSES THAT HAVE A PLASTIC BODY! Make sure you use or purchase replacement fuses

that have a ceramic body, such as the original fuses have. A proper replacement is shown available here.

Many new replacement fuses

have plastic bodies, that can distort from heat and cause the fuse to make intermittent contact with its end connectors. These

plastic body fuses are a real problem, stay away from them!

If you now suspect the relay may be at fault,

jumper pins 30 and 87, while listening for the fuel pump motor, or attempt to start the engine and see if it runs. The

relay position shown below is for the 1982 to mid-1985 528e. It's location changed sometime after mid-1985 to the

other side of the large black connector, between the relays. You should know that even if you can hear and feel the suspect

relay "click" when activated, that is not an accurate indicator that it is fully functioning, since the contacts are what

usually fail due to pitting and arcing and prevent enough power from being applied to the respective circuits. You must check

with a voltmeter at the fuse or relay operated device, if you don't have a known working replacement relay to substitute.

This also applies to swapping relays around, which may also be faulty and has certainly been known to happen.

Here is an additional input (fixed

link change 8/14/2011) from our friends across the pond, in the UK, from forum.bmw5.co.uk, titled

E28 535i and 525e Motronic non-start trouble shooting guide.

Update January 23, 2012 -

And

another Bosch Motronic troubleshooting article, by Toby Rozell of OKinjectors, with a lot of photographs, at this link.

If your relays are old I

strongly suggest you replace them all, as I've seen many that are really troublesome

on at least a half dozen different E28s, over the past year. I also suggest you always carry a few spare

relays... certainly ones to replace the main, fuel pump and headlights.

With respect to keeping relay tabs and socket connectors clean, I suggest

you purchase CAIG Labs DexoIT and SHIELD. I've been using CAIG Labs products since 1959, when it was known as Cramoline. You can find the products here. I apply DeoxIT SHIELD to all fuse and relay contacts

once every year, which takes less than an hour. Every second year, I reapply both DeoxIT and SHIELD to all fuse, relay and

grounding connections, as well as all device connector contacts, such as sensors and cable connectors. In the past 28 years,

the vehicle has never had an electrical connection failure, other than a fuse or relay due to age, not due

to electrical contact problems. Over 60% of all E28s that I have worked on have had various questionable electrical connections,

so the problem is well known but not properly dealt with, in my experience with many E28s. I can't overstate the need

for regular maintenance routines involving CAIG Labs products, to help insure against assorted electrical connection

problems, on the E28.

Battery Going Dead -

If your battery isn't holding a charge, but is known to be in good condition and your charging circuit is working properly,

look for something that might be draining the battery when the car is parked. Normal drain on the battery is usually between

20 and 25 milliamps, as measured on my car and several others that had no battery drain problem. If it is much higher on your

car, something is consuming it, such as as stuck mirrior heater relay, bad antenna circuit, etc.

Update Nov. 12, 2006 -

Fuse holder arms/tabs that have been overheated and

are now loose at their base, can still be used by installing a 7/16-inch I.D. silcone rubber O-ring to apply tension across

the arms, insuring a stable connection. Make sure you use silicone and not vinyl or neoprene, since silicone will last longer

than you are probably going to have the car.

Update Dec. 20, 2006 -

E-mail from other E28 owners identified potential problem with auto

store generic O-ring material failing quite soon after installation, versus experience with silicone material, discussed

here. The discussion includes links to quality O-ring sources.

|

| A fresh #2 yellow pencil eraser will clean and polish relay contacts. |

Update January 11, 2011

There is no small amount of confusion that some new E28 owners have, as to what truly

worn out distributor cap contacts look like and what does a worn out rotor contact look like and they should

be replaced, because they are responsible for various performance problems. Unfortunately, no really good photographs exist,

showing a good view of faulty distributor cap contacts, or the rotor contact. The highly regarded Bentley BMW E28 5-Series

manual only show a crude drawing (page 8-5), The BMW Factory Service Manual has no picture at all of the contacts (page 12-35

and 36) and the Haynes BMW 3 & 5 Series Repair Manual only has a poorly illuminated picture (page 1-18) which shows no

contact detail. Lastly, my search via Google didn't show anything better. So, how is someone supposed to know what is a bad

distributor cap and/or rotor? What does a worn out cap and rotor actually look like?

|

| - CLICK ON THE PICTURE TO EXPAND IT - |

A brand new Bosch rotor, showing the condition of the contact

tip, which looks like polished brass.

|

| - CLICK ON THE PICTURE TO EXPAND IT - |

A worn out rotor contact tip, which

has an excessive amount of contact surface deterioration which has significantly reduced energy transfer capability.

Yes, some contact deterioration is normal, but how much is too much? The point of these pictures is to show that

this rotor is worn out! It was creating problems...

Rod,this cap & rotor have somewhere between

15-20,000 miles on them. I can always tell when it is time for a change since when accelerating heavily from approximately

45 mph without letting it down shift, (remember I have automatic) there will be the occasional "miss" or "skip" . Interestingly,

it still starts just fine. Idle before getting to running temp is a little erratic. Not rough, just not steady. Also interesting

is that gas mileage is not effected as bad as one would think. When replaced I always do plugs as well. Smooth as always when

done. $160 total in parts including the hard to find Bosch WR9LS plugs. (waynet at the MyE28.com forum)

|

| - CLICK ON THE PICTURE TO EXPAND IT - |

Worn out distributor cap contacts and the rotor contact

surface shown above, can contribute to creating other performance problems... intermittent stumble on acceleration, random

hesitation while in a lower gear at a light load (like through a school zone, or in a neighborhood) and flat out poor performance

at high revs.

UPDATE May 4, 2010

Battery Charging Problems -

In addition to the infamous burned-out lamp for the battery charging indicator in the

dash, when you turn the ignition on, there is another no battery charge indication, caused by badily worn alternator commutator

brushes and resultant dead battery. In fact, I think it may be the cause of more rebuilt alternator purchases, that test poorly,

versus actually inspecting the regulator/brushes assembly and replacing worn out assemblies. A good friend of mine with

a 1988 528e recently went through this very situation, with a near dead battery and no battery charge indicator light in his

dash... usually meaning that the lamp is burned out and alternator field coil isn't getting any voltage to operate with. But,

not so with a 1987 or 1988 528e, with a small resistor in parallel with the lamp. The alternator should still be generating

power, but his wasn't.

Long story short, the brushes were worn out, certainly one of them, as shown below...

|

| - CLICK ON THE PICTURE TO EXPAND IT - |

Note the significantly smaller size of rear most brush. And

look at the overal major difference in brush length between the old assembly and the new assembly, shown below.

|

| - CLICK ON THE PICTURE TO EXPAND IT - |

You can see the major difference in brush length between

the old and new assemblies, removed from the rear of the alternator. In the case of this 1988 528e, it is a brush assembly

for the 90 amp model alternator, purchased from a local NAPA dealer for about $43.00. Certainly much less money than a rebuilt

alternator! So, don't forget to check the alternator brushes, which may be very nearly worn out and time for replacements.

And thanks to my friend Wayne, for the above pictures.

|

| - CLICK ON THE PICTURE TO EXPAND IT - |

The regulator/brushes assembly above is from my own

1983 528e, which I replaced today (4/30/2010), after looking to see what its condition was, after Wayne's problem. In reviewing

my records, I saw I had examined it earlier during my 122,523 mile tune-up, when I replaced the alternator mount bushings and the

brushes appeared serviceable at that time. It is the original regulator, now with 12k more miles on it at 134k miles.

I replaced it with a NAPA VR506 part, made by Bosch, $43.88.

GROUND PROBLEMS

There are several major ground points on the 528e that can create problems that

may look like a relay, fuse or component problem. The four major electrical ground locations are:

G102 - Located on the front of the left hand fender, above the battery, where the battery

ground is connected.

G103 - Above the starter motor on the bottom of the intake manifold.

G200 - Under the drivers side of the dash near the brake pedal.

G301 - Under the left hand side of the rear seat.

Not an uncommon ground problem -

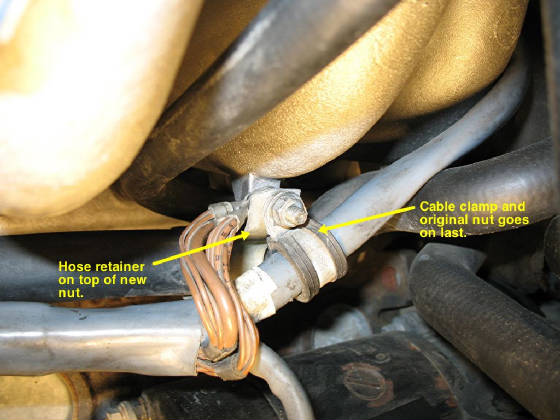

Here's a recent problem involving the G103 ground on a fellow 528e owners car, which

was intermittent and as such is always a difficult problem to find. But, when it happened, it did provide clues as to

where to look... with erattic starting and idle speed, random increases in temperature gauge readings and what

felt like a bad throttle switch adjustment problem. If you look at the E28 Ground Distribution text file, you can see these problems are all potentially possible with a fault at G103, since it is the ground point

for the devices that would be involved, which is what actually turned out to be the problem! Look at the pictures closely.

|

| - CLICK TO ENLARGE - |

|

| - CLICK TO ENLARGE - |

|

| - CLICK TO ENLARGE - |

|

| - CLICK TO ENLARGE - |

Evidently, when the coolant hoses were replaced several months

ago, the G103 nut was not properly tightened and worked its way loose, creating the intermittent running problems. Also, the

position of the wire lugs were incorrect with respect to their position on the ground stud... this may have been changed at

an earlier date and not the last hose change service. With the grounds properly restored, the car now runs as if it had a

fresh tune-up! Pay attention to grounds, they can create some very frustrating intermittent problems. And use the E28 Ground

Distribution text file, to help point you to what may be the actual cause of the trouble... a poor ground associated with the potential problem

device or function.

Update May 2, 2007 -

The elusive G200 Ground Point behind the dash.

Seems quite a few people have difficulty locating the G200 ground point, which is only

referred to as "near the brake pedal bracket", and the ETM black and white photos are pretty poor and don't help much.

I've taken two pictures of my dash backside and hope these help you.

|

| - CLICK TO ENLARGE - |

You'll probably have to move some of the wires to see the

ground point, but the cluster of brown wires will help you find the bolt securing the ground wire lugs. Mine are in excellent

shape after 25 years, thanks to DeoxIT which I apply about every two years. Very necessary in the jungle type humidity of

Virginia's summers. You may also find some of the fabric tape wrapping around the wire groups is falling off, so have some

small cable wraps handy to clean this up. Don't over tighten the ground bolt! It is only screwing into a thin metal tab and

you can strip it. If it is stripped, use a metric nut on the backside of the bolt or a larger self-tapping bolt/screw.

While you've got this part of the lower dash open, remove

and clean the Window Power Relay and the Start Relay, which you'll have next to the Window Power Relay if you have an automatic

transmission. Manual transmission E28s don't have a Start Relay.

UPDATE Sept. 4, 2009

Intermittent Power Window Operation -

If

you find that your power windows don't go down or up when you press the buttons and you have to try a few times to make the

windows move, it's most likely due to dirty and worn electrical contacts inside the switch. The BMW power window switches

have eight (8) contacts associated with each button, so they are not a simple switch configuration only consisting of two

contact configurations... UP and DOWN.

When you open up the switch, do it slowly and do not let

the two sections come apart quickly. Separate them partially and slowly and then place the switch with the buttons

facing down on a soft surface, then lift off the bottom connector piece as shown below.

You'll see the lamps and the brass contact strips that the

push button contacts slide against and the contacts at the base of the brass contacts strips, which on this switch are in

decent shape, but not the contacts on the switch shown below.

This switch came out of a junk yard E28 and worked perhaps

one out of ten attempts, due to its badly contaminated contacts. This level of contamination usually requires gentle polishing

with 2000 grit wet/dry paper, as contact cleaners can't really do a lot with such contacts. I've actually used Simichrome polish applied with a Q-Tip with very good results on some really nasty switches. You have to cut through the junk and then

apply the chemicals. As I've indicated above, I use CAIG Labs DeoxIT and SHIELD, which brings the old switches back to 95-99%

operation.

Make sure you note the position and orientation of the buttons

when you remove them from the switch body, as they have to go back in the same place and orientation, or the switch won't

work. There are four contacts on the button and most have to be polished with 2000 grit wet/dry paper to get the contacts

back in shape. When reassembling the switch, make sure the lamps go into the center of the button springs and everything is

aligned properly. Once you've got the switch back together, don't forget to apply DeoxIT to the switch connector tabs and

plug and unplug the switch several times to help clean and lubricate the socket contacts.

Problems with the dash instruments.

If you haven't been able to correct problems with some dash instrument or indicator,

using your Bentely manual and other wiring diagrams, you may want to consult ProgRama, Inc., who specializes in BMW dash cluster repairs.

Lastly, here are two good resources that can help you troubleshoot starting problems,

as well as covering other electrical problem subjects... Voltage Drop Testing and The Starting System. Lastly, keeping the battery in good shape, especially during periods when your BMW is not being used,

such as mine which sits during most of the winter, is very important. I have found that the Deltran Battery Tender Plus, available

at the Battery Mart, is an excellent way to keep your battery in top shape.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|