|

|

|

|

Maintenance tips, comments and links about

performing various types of maintenance.

(click this link to go to this update

location)

|

|

Replacing the Upper & Lower Control

Arms.

Based on asking a great many E28 DIY owners, over a dozen

or more years, the E28 typically needs its upper thrust arms replaced, somewhere around 35,000 to 45,000 miles of use

based on service invoices or parts invoices that had the mileage recorded when the parts were installed. The lower control

arms may not actually require replacement, but I've always replaced them at the same time, rather then go back under the car,

again, sooner than later. That's been the case with my upper thrust arms and the typical service life other E28 owners

have reported to me, and my E28 now getting its third set of replacements at 127,000 miles. However, this time I

am installing a pair of upper thrust arms that use the BMW 750i bushing pressed into a modified E28 arm, that came from Lemforder

through Steve Haygood.

You'll know when it's time for replacement, because you'll

start getting what feels like wheel/tire imbalance vibrations in the steering wheel and during times of light braking at about

52 MPH. The vibrations can occur at varaious times and appears to be very sensitive to vehicle load, such as with additional

people in the car.

______________________________________________

A Special Note -

November 26 2009

I've

had more than a few comments from people who have followed my

steps on this webpage, while renewing their front suspension and steering components, but still have disappointing handling after completion. In fact, today one of my website users who had completed

a frontend rebuild on his E34, said his handling now felt like "driving a truck pulling a trailer behind and the fishtail

effect." This is a good analogy that describes what typically happens if there are rear suspension problems, that have

been over looked and not addressed.

In all cases that I have been told about,

the problem has been due to worn, out of spec

rear suspension components, namely the shocks

and subframe bushings (shown here) and several

other components like a torn rear differential mount, badily worn pitman arms, a broken

anti-sway bar mount, bent push rod(s), etc. It is very important to make sure the

rear suspension components are all working properly, in concert with

the front suspension and everything is in proper alignment.

______________________________________________

June 2006

Initially, I thought I had a potential wheel bolt torque problem, causing a small lateral run out error with the wheels. Tests below showed this really wasn't the problem.

|

| Lemforder Thrust (upper) Arms with 750i bushings and stock (lower) Control Arms. |

|

| Machined bushing face of the thrust arm with its larger bushing. |

|

| Various tools used to remove the ball-joint connection... only two are preferred. |

Getting it up in the air -

(NOTE- This write-up was done before I had the EZcarlift

(shown here). However, you still need a way to get the car up on its wheels so that you can get to the bushing bolts and tighten them

while the suspension is preloaded. Some have suggested leaving the bushing bolts loose and driving to the alignment shop and

preloading it there while up on a drive-on rack. I don't like this idea as it would allow some significant flexing of the

loose bushings, possibly damaging them.)

I prefer to use a combination of ramps with additional height

gained by using 4x4s (clamped because they were just glued and screwed together, to replace two warped 2x8s) and standard

3-ton jack stands placed at appropriate locations, for both safety purposes and support when the wheels are off the vehicle.

This requires that you have some decent floor jacks to permit getting all this properly positioned, since both the front and

rear has to be elevated to a level height in the case of doing Control Arm bushing replacements and getting them accurately

pre-loaded and tightened. But once setup, you have sufficient clearance to perform most underside projects, within reason,

working on your back. So, give some thought as to what other underside projects you might want to also tackle, while the car

is up in the air. Brake job? New shocks?

|

| Measuring wheel lateral runout with .001" dial micrometer |

Checking wheel and brake rotor lateral runout

-

Checking the lateral runout of the wheels, to see

if they are in spec and what effect does wheel bolt torque have on wheel lateral run out, using both lightly oiled and dry

thread bolts, tightened to 74 lbs-ft. BBS does not publish a spec for run out, so I used the "preferred" wheel run out spec

most auto mfg.'s use which is "less than 0.020". My front wheels measured 0.013" and 0.015".

Potential excessive wheel bolt torque was thought

to be the cause of steering wheel vibration, when it first surfaced about a month ago. However, the difference between the

torque actually applied, using lightly oiled and dry wheel bolts did not show any change in wheel lateral runout! Not with

the wheels currently being used (E39 BBS style 29) and also with my earlier 19-spoke 390mm E24 TRX wheels, which I also tried

this test on. The earlier steering wheel vibration was due to early signs of control arm bushing/ball joint failure?

The wheels were removed and the brake disc run out

was checked on both wheels. Balo spec is not to exceed 0.006" measuring at 1/4" from the disc edge and the disc tightened

to wheel bolt torque spec, or in our case 74lb-ft + or - 7lb-ft. One disc measured a maximum of 0.0015" and the other

measured 0.0025", well within Balo spec. I'd also add that I tested again with dry (wheel bolts washed in solvent and hub

threads swabbed out with solvent) and lightly oiled wheel bolts torqued to 74lb-ft and I saw no difference in the brake disc

measurement run out figures.

|

| Measuring disc "run out" of Balo front disc. 0.0015", spec is 0.006" maximum |

Large flat washers are used under the head of the wheel bolts

to approximate the contact area the wheel bolt hole pads make with the face of the brake disc hub. The washers also prevent

flaring of the bolt hole edge on the face of the brake disc hub, which can rise above the surface of the hub face, creating

a wheel run out problem. Because I am running E39 style 29 wheels, you can see the aluminum hub-centric adapter

ring on the wheel hub, which is addressed on another webpage here.

_________________________________________________________________________

PLEASE NOTE

- All fastener torque settings are made with Snap-on TORQOMETER

TE series 2% accuracy torque wrenches,

calibrated annually. Sorry, but my

experience with $39 I-Beam type torque wrenches is that they're junk!

If you need assistance obtaining Snap-On

products, feel free to contact

_________________________________________________________________________

Installation of new front suspension components

has been delayed, as the original attachment hardware (nuts and bolts) have been damaged! Some of it is clearly old and used,

such as the locknuts and the bolts appear to have been subjected to a worn 6-point socket or 12-point socket on an air

impact wrench. The flats are badly damaged and all hardware must be replaced! And I paid money for this level of work! More

delay as only a few pieces are available locally, so back to Mr. Haygood for parts.

Update

July 31, 2006 -

New hardware has arrived and work can resume. Cost was $34 including the

stainless steel heat shield, not originally on this October 1982 build, nor was it installed by my BMW dealer after BMW advised

its dealers to do so in 1984! The right Thrust arm bushing is cooked!

|

| New hardware to replace damaged hardware. |

|

| Main front suspension component locations - CLICK TO ENLARGE |

Update Sept. 20, 2006

Special Note...

The

three bolts at the base of the strut, which attaches the steering arm, should be locked with a heavy duty "Red" thread locker,

such as Loctite 270 (BMW p/n 81229400086). FYI - Loctite 270 has been replaced by Loctite 271. Because a thread lock

chemical has been used, the bolts will be difficult to break loose and remove, unless you apply heat to the bolts area,

first. I use a Weller SP175 Marksman Mini Iron (175 watt 900 degrees) with very good results. Simply place the soldering iron tip on the bolt head for several minutes.The

Bentley manual specifies that Loctite 270 should be used, but makes no mention of using heat to remove bolts locked with Loctite

270, or equivalent! DO NOT USE IMPACT tools to remove these, as you may break off the bolt head! Do not attempt to use a large

breaker bar without first applying heat, or you'll break the bolts.

Also, the heads of these bolts are not very tall, so

make sure you use a 6-point socket that is in good shape and fits the bolt lands snugly and isn't too loose. If the lands

are damaged, as mine were, good luck! These are 10.8 hardness, 130,000 psi minimum yield strength bolts, but torque should

not exceed 72.2 Nm or 53.2 lbs-ft. With "Red" thread locker applied, bolts should be tightened to 65 Nm (48 lbs-ft). A data

sheet from Loctite about the "270" and "271" products is available here.

Lastly, several people have suggested that "Red" thread locker

need not be used. That is sheer folly and a real danger to you or anyone who operates the vehicle!

|

| Steering arm bolt locations. |

Attempting to confirm control arm bushing problems

While the Bentley manual and others have suggested grabbing the

control arms with large water pump plyers and checking for excessive movement of the control arm, this process doesn't easily

identify boarderline bushings, that seem fine when you're all alone driving the vehicle, but exhibit shimmy under braking

or at various speeds when additional people are in the car, sometimes just one additional person, such as was my case. Further,

looking at the bushings may show nothing, unless they are in really bad shape, which I didn't consider

mine to be... and I couldn't see anything wrong with them while on the car.

Still, with all the symptoms, especially the steering shimmy above 50 mph, I figured the vehicle probably really did need

its third set of upper and lower control arms, after only 35,000 miles, even though water pump plyer tests and close visual

inspection showed nothing apparent with the current arm's bushings. It was only after I had removed the arms, that I could

easily tell that they were trouble.

|

| Stock 528e thrust arm bushing. |

The primary culperts are the upper thrust arms, with the right one showing heavy wear (and heat stress), the left bushing

looking better, but still with very deep major cracks or breaks and bushing separation on both sides, when placed

in a large vise and moved as it would move in the vehicle. The bushing wear was there, very easy to see. A further test was

to place both the old thrust arm and the new thrust arm with a 750i bushing, side-by-side in the bench vise and move them

together to feel the difference. The removed thrust arm was clearly at the end of its service life, with its rather shocking

amount of movement and significantly less resistance to movement, which couldn't be felt while on the

car and using the water pump plyers test! Based on my own observations of this, I would say the shimmy at braking,

especially with several people in the car, is a very good indicator about probably needing upper thrust arms...

and perhaps ball joints, too, as noted below.

In view of the bad condition these thrust arm bushings were found to be, once off the car, I'd suggest that the water pump

plyers test is not an absolute test of actual bushing condition, if they are marginal. It did

not show my bushings to be in such a bad state!

Update May 15, 2011

Another heavy duty UCA replacement option... Spherical

Upper Control Arm Bushings, by Moosehead Engineering, are now available for the E24, E28, E31, E32 and E34. I have no personal experience with these bushings, but I will be adding

user experiences about this product, as I find them. It's certainly a potentially good product idea, but I have concerns about

potential harshness and noise, based on my own experience with 'poly' type UCA products in the past, which I found were not

an acceptable upgrade for my use, which is long distance travel and weekend drives. The additional road noise and harshness

the 'poly' bushings created over poor road surfaces was not at all acceptable to me. If I was tracking the car, it would be

a very different consideration, of course.

|

| New thrust arm with 750i bushing (left) and stock worn out 528e thrust arm (right). |

Update April 8, 2008

What happens if you don't "preload" the suspension

correctly?

Here is a picture of an upper control arm removed from a 528e, sent to me by a BMW friend

who had to replace the control arms after he had them replaced earlier, by a shop that did not preload the suspension! You

can see that they tore and are in much worse shape then mine were. I've been told by others that the bushing may last a week,

or perhaps two weeks, before it fails like this if the bushings have not been properly preloaded. Don't screw up with this!

|

| - CLICK ON PICTURE TO EXPAND IT - |

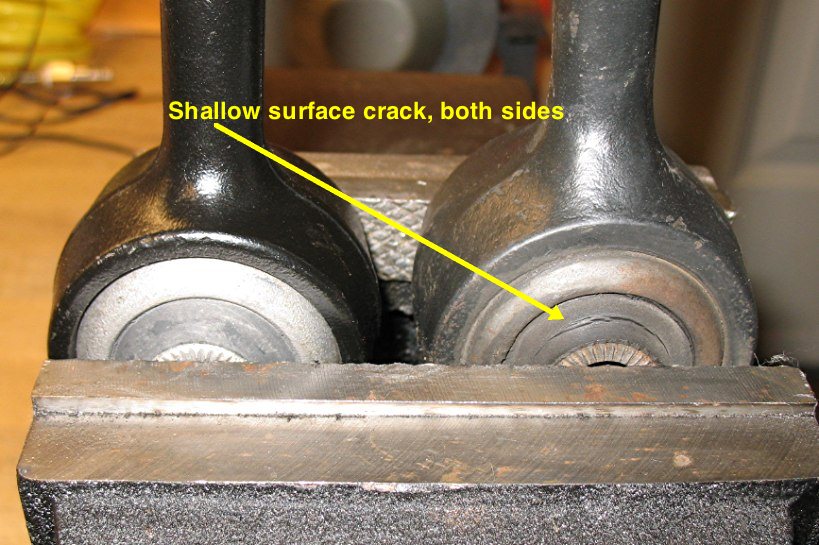

Inspecting and comparing the used lower control arm

with a new replacement control arm, placed side-by-side in the bench vice (shown below), showed no detectable differences,

other than the old arm bushing feeling a tiny bit less rigid compared to the new arm bushing, while moving them both at the

same time. Not very scientific, but the lower arms certainly had less of a difference then the upper thrust arm bushings clearly

showed. The cracking visible in the rubber bushing surface is surface cracking with no depth, as determined when

probed with a small needle. Not the same as the upper thrust arm cracks or breaks in the rubber bushings which are very deep,

perhaps penetrating the full depth of the rubber, at different points around the bushing circumference.

|

| New lower control arm (left) and old lower arm (right) |

There was, however, a bad cut in the ball joint boot

on this control arm (below) that was not visible while on the car, as it was next to the brake backing plate. It had allowed some

of the grease to escape and dirt and water to get in over time and the operation of this ball joint is sloppy and notchy,

suggesting bad wear on the joints surfaces.

The right front tie rod also had a sloppy ball joint and mistreated tube and

clamps, both were over tightened and one clamp bolt head broke off during my removal. Use of Vise Grips to rotate

the tie rod tube, without ever fixing the problem (replacing the rusted and jammed tie rod) shows unacceptable judgement and

workmanship on the part of the technician who last worked on this! The left tie rod was only slightly less damaged, but was

totally frozen and could not be adjusted (it was not serviced) but both ball joints were sound.

So, while the lower control arm bushing appeared to still be performing, the

loss of lubricant and wear to the ball joint and another sloppy ball joint on the right tie rod, certainly required that these

be replaced. It probably contributed to the shimmy problem, too, if only in a small way, but was there none the less.

With respect to the issues of damaged attachment hardware, requiring replacement and

unacceptable workmanship by people employed by BMW dealers or so called qualified independent servicing shops, I'll certainly

be conducting my own inspection of completed work, in the future, before my vehicle leaves such facilities. I'd suggest

others do the same, given the results I've seen on other BMW's I've looked at or worked on.

|

| Removed tie rod with sloppy ball joint and badly treated shaft. Frozen, can't be adjusted! |

Assembly

Aside from taking this opportunity to clean up the area, with the suspension components

out of the way, don't forget to chase the threads in the base of the struts, where the steering arms will be reattached using red

thread locker.

|

| 10mm x 1.50 thread tap with 1/4" drive extension. |

You may have replacement parts with different attachment

configurations, such as below, where one ball joint uses a castle nut and cotter pin to lock the nut, while the other uses

a nut with a nylon insert to lock it. You can see the difference in the shafts. Never use a nylon self locking nut on a shaft

designed for a castle nut!

|

| Threaded shaft for castle nut (left) shaft for nylon insert locking nut (right) |

When replacing parts that use a castle nut and cotter

pin attachment, give thought to the position of the cotter pin to permit future work and easy removal and replacement. Below,

the left tie rod arm ball joint is attached to the center link with the ball joint cotter pin hole positioned so that the

cotter pin can easily be accessed from below, since its head is at the bottom of the assembly. Tapping on the rear edge of

the ball joint housing (not on the large cap) with a plastic mallet, will help seat the tapered shaft, so that it won't rotate

while torquing down the shaft nut. Position the other castle nut/cotter pin ball joint ends in the same way, allowing good

future access.

You'll appreciate this little attention to assembly

detail, when it comes time for parts renewal... as will the next person who works on it, if you don't. The white stuff on

the ball joint threads is not Lithium... the new ball joints were removed from the tubes, cleaned and lubed with DuPont Krytox

grease! Water proof and vastly superior protection.

Update April 27, 2007 -

I've had a number of E-mails indicating that trying to find DuPont Krytox grease in

a small quantity has been very difficult, if not impossible to find. Indeed, it is difficult to find, but the Loctite

product is identical (so I am told by DuPont) and is readily available from major sources, such as Amazon in a 3 Oz. tube for less than $10. Let me know if you have a good DuPont source.

|

| Left tie rod attachment to center link next to steering pitman arm ball joint |

|

| Parts ready for installation on the car. |

I use small box tops to contain the hardware that

is going to be installed. You can see that I've already attached the lower Control arms to the steering arms (BMW calls them

"tie rod levers", Bentley calls them "steering knuckles") and have properly torqued the ball joint nut. I've found it easier

to just install the lower Control arm and not the Thrust arm at this point, as it makes it easier to position the steering

arm back on the bottom of the strut. With both arms attached to the steering arm, it gets a bit unwieldy. Besides, the Thrust

arm is easy to attach to the steering arm once the steering arm is installed.

Missing Heat Shield Cooked UCA Bushing!

As I indicated earlier, the lack of a heat shield

on the right side Thrust arm resulted in the bushing being cooked, to the extent that comparing the two Thrust arms mounted

side-by-side in a vice, showed the cooked bushing to have much less resistance to movement. Upon close inspection, it appears

a heat shield was never mounted at the factory, as there are no marks on the mounting area or the attached flat nuts.

It simply was never installed.

|

| Heat shield installed on right side Thrust arm bushing mount. |

|

| Heat shield attachment. |

If you have an early model E28, I'd certainly check

to see if the heat shield is in place, as it may never have been installed, or not replaced during Thrust arm replacement

or exhaust down pipe work. It clearly is needed, given what the heat did to my stock Thrust arm bushing. Without a heat shield,

would the plastic in the larger 750 bushing start to deform? Become soft or brittle and fail? I only discovered this heat

shield, after seeing it in the front axel parts breakdown, while identifying replacement attachment hardware to order from Steve Haygood.

Steering Box Center Marks

While you're under the car, you might want to clean off the

steering box center index, perhaps adding a bit of white paint to make the index marks much easier to see. The Bentley manual

picture of this is confusing, as it looks like the universal joint seam is the reference point, not the collar with the raised

mark on it. A few other tips follow...

|

| Convert an old 5/8-inch wrench for swaybar link use, by grinding it down. |

Poor Quality Anti-Sway Bar Links

While preping the car for the BMW CCA NCC May 4, 2008 concours,

I discovered that the anti-sway bar link joint boots had failed, after only 2300 miles, exposing the joints to the elements!

As can be seen below, the boot has torn away from its retaining ring and this has happened at both ends of this link and one

end of the other link. Note how the rubber has deteriorated. Was this very old stock, or simply poor quality boot rubber?

The only identification on the sway bar link, is the letter

"K" within a circle. This link came from a trusted supplier. But, I have seen some on the Internet, which appear to be identical,

based on their boot shape.

The "K" brand link (bottom) compared to a Meyle brand link

(top). This is the only end of the two "K" brand links, that the rubber boot is still intact... but certainly showing major

rubber deterioration. Note the major difference in the boot configurations and the additional shaft welding on the Meyle brand

link. The Meyle boot also feels much thicker and more robust. The "K" brand was used to replace high mileage Lemforder

brand links, in 2006, which had started to develop the common creaking noise that these links make at the end of

their service life. BTW, the boots of the high mileage Lemforder links were still intact and sound! Watch out for these "K"

brand things, they are a POS, in my opinion.

NOTE - I thought I had forgot to properly

tighten the sway bar end of the left front link locking nut, as I discovered a knocking sound within a few miles

of road testing. I tightened them to 15ft-lbs, as I have with the previous link self-locking nuts. Yesterday,

after some serious backroad driving on surfaces with some major undulations, forcing the suspension to work hard, the

frontend again started making a lot of loud knocking and clunking noises, much worse then the previous racket. A

quick check (smack the bottom of the sway bar with your palm) showed that now both anti-sway bar link nuts were loose at the

bottom attachment to the anti-sway bar!

The problem is that I used my earlier tightening torque, but the Meyle links required

different torque settings, as shown in the Bentley manual in Section 16 - Page 7, at the bottom right corner of the page,

in a box labeled "Tightening torque". Described as white chrome nuts, (as used on the Meyle links), the required

torque was 24ft-lbs, up from my earlier yellow chrome spec of 15ft-lbs. My error, I should not have assumed the nut torque

would be the same. Watch out for this when using different brand replacement parts... their attachment tightening torque specs

may be different.

Update August 25, 2006 -

Finally finished and all back together, with the bushing

bolts torqued down with the specified vehicle weight pre-loading in place. Certainly worth all the effort,

to get the steering and front suspension back to very tight and responsive condition, probably even more so

than stock was, with the use of 750 bushings in the Thrust arms. Yes, the steering shimmy, braking shimmy and the other

associated problems are gone! Let's hope these 750 bushings last a bit longer.

|

| Finished! View of the right front underside, completed. |

|

| 150lbs of sand bags in each seat and rear center to preload for alignment. This is CRITICAL! |

SPECIAL NOTE -

I have seen quite a few comments about the need to preload the suspension prior to performing

an alignment, with many of them suggesting that this step is not actually needed, or just to simply replicate the drivers

weight and perform the alignment. My mechanic friend and me discussed these suggestions and his position was that BMW specified

this preload condition because it designed the suspension and certainly knew considerably more about it than probably any

DIY owner, weekend auto crosser, or corner alignment shop! We actually looked at the resulting alignment results, with and

with out preloading and making several short runs to permit the suspension to settle and observe the handling feel, with one

and two people in the car. The bottom line is FOLLOW THE BMW SPECS and do it right!

|

| Friend and Master Mech., Roger Davis of VIP Auto setting up for computer alignment. |

On a very personal note -

I am sorry to report that my Master Mechanic friend and co-owner of VIP Auto, Roger

Lee Davis, died June 28, 2010. He had been my mechanic of choice for our other vehicles for the past 22 years and did, as

shown above, work on my BMW at my request, since he did not activly service BMWs as part of his normal business. He was an

old school mechanic, with a wealth of knowledge gained from many years of hands on experience and pride in his work. And he

always took the time to discuss and debate issues I raised about many vehicle maintenance processes and I raised many over

the years. A combination of things I'll be hard pressed to find, in another person, younger in years. I will miss him, his

skills and the time he devoted over the past 22 years, keeping our vehicles on the road. He was a man who always took

care of business.

Update April 23, 2008

Final

thoughts...

I like the feel of the 750i bushings, a bit stiffer and what sounds perhaps a bit more noisy,

but not as noisy as the urethane bushings I once tried, nor as harsh. In fact, several E28 owners, most recently Philo, talking

about his E28 M5 said "I have Grunts bushings in there now (third set) and I think I'm going to go with the 750s this time.

The Grunts, or urethane bushings in general, develop a memory and become constantly sloppy. The reason I went to urethane

was because I had a bad experience with the 750s.., I had the green plastic inserts crack and fall out which then made the

front end plain dangerous!" Philo recently removed the blue polyurethane bushings, which look like they were disintegrating. Another bushing of the same type from a different E28 is shown here.

Several others have commented to me on their urethane bushings

becoming sloppy, too, as well as being more noisy than stock BMW bushings. I hope that these current generation 750i bushings

in the E28 arms remain stable and provide good service life.

The bottom line, now with over 500 miles of testing at speed

and on west Virginia twisties, is that the overal improvement in my steering and front suspension is quite evident, making

the car feel much more precise and controlled. Road irregularities now have little effect and moderate stuff does not require

small steering corrections, as was necessary before the work. The car continues to feel stiffer in fast corners, especially

with additional people in the car. Several people have suggested that the larger bushings are probably not responsible for

the increased roll resistance, but I think they are in error... nothing else changed to explain this performance observation.

Surprising how much precision and performance can drain away

over time and we really don't notice it, until it is renewed back with fresh components, bringing back what BMW

intended. It brings a smile to my old face!

And always, special thanks to my wife, Shelley, who supports

my desire to do these projects, lends a hand when she can, loves the car and is a great co-pilot during road testing after

the work is completed. Over the years she has developed a keen sense about what the car is doing, or not doing.

All male wrenchers should be so fortunate.

- Replacing the rear suspension bushings using the right tool

- Removing a broken bushing sleeve.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|