|

|

|

This

page last revised November 14, 2013

Earlier Modifications and maintenance performed

at 105k miles...

- Bilstein HD shocks and front suspension bushing

replacements.

- New style BMW M20 head gasket and Torx headbolts updates.

- New clutch assy., timing belt, water pump,

poly alternator mount bushings,

external fuel pump and all new fuel and water hoses, including clamps.

- Fusebox and electrical

connector maintenance and relay replacements.

The vehicle is rigorously maintained, including use

of synthetic oils and lubes and Zymol wax and leather treatments.

Here is a full listing of the Maintenace and Modifications History performed on this BMW since day one, in

.pdf format. It is updated as changes are made. Invoices and receipts for all labor and parts since day one, including

a copy of my original 1983 GE business auto lease agreement, are on file.

Internet resources for helping you with your

BMW E28 work are:

Update March 26, 2013 -

(Removed low use Forums)

Here is a good parts resources list, all

of who I have done business with. Vendors endorsed by MyE28.com. Unfortunately, BMW of Chattanooga is no longer providing parts! Sorry to lose you as a very good resource, Brian, I hope to have your

resources again, some day. In the mean time, I direct your attention to a thread on MyE28.com, talking about where to buy needed parts, now that Brian is out of the picture.

UPDATE

- I've recently started doing business with Blunt Tech, based on some good experiences by others. You can reach Blunt Tech

here via their posting on MyE28.com.

And you'll see references to Steve Haygood

on many of my web pages, who provided me with many BMW parts over the years. Unfortunately, Steve is no longer providing this

service and many E28 owners, including me, are sorry that he isn't.

Additional parts resource comments were recently posted on MyE28.com

at this page. Please keep in mind that if you are having parts shipped to you, there is the question about the length of time it will

actually take to receive the part... when the parts guy has some time to pack and ship stuff? It's being drop shipped

to you from a supplier? The firm has a real shipping department? Certainly important if your E28 is out of service until the

required part is received. Price is one thing, prompt parts delivery is another.

Update Sept. 8, 2011

All of these web sites will lead you

to all sorts of other BMW resources. Check them out. Comments about this website were made by my peers and posted

here, which I was very happy to see. And a recent comment by Mike Miller, technical editor, ROUNDEL, made here about this website and my Email to him about "Thanking Our Mentors". My 10 minutes of fame!

One very important point...

All information presented

here is for informational and documentation purposes only and is not to be considered as "complete instructions" on how to

do it. I am simply showing how I did this work, why, a few tips that may help you with the same work and what the completed

work resulted in with respect to improvements with my 528e. Further, I assume that the reader has good automotive maintenance

skills, correct tools and at the very minimum has a copy of the Bentley manual (ISBN 0-8376-0318-8). Also having a copy of the BMW Factory Service

Manual, Part No. 01 51 9 699 517, is worth the cost.

I no longer answer questions directed to me via Email,

so please don't send any. They will be rejected, automatically, by my Email server.

- 2004 Modifications -

|

|

2004 brake, suspension and wheel modifications...

|

| E32 Disc Brake Rotor and Caliper |

E32 BIG Brake Upgrade

The E32 (7 Series) brake upgrade is a very good improvement

in braking power and it's easy to accomplish as it is a simple "bolt-on" process... take the original pieces off and put the

new pieces on. The E32 rotor is 302x28mm, versus the stock E28 front rotor which is 282x22mm. You'll need to have 15-inch

wheels, as the E32 caliper won't fit inside a 14-inch wheel. I upgraded to 16-inch wheels which I discuss further down this

page. My original 390mm TRX tires/wheels still fit. Rear brakes were also upgraded to E34 530i units, but I went back to the

stock setup as the E34 brakes made no significant difference, after testing the two setups.

|

| Stock rear brakes used, fitted with fresh Balo rotors and painted |

They may have been of value if I was tracking the car, but

even with very aggressive back roads driving they were no better then the stock brakes with fresh Balo rotors and pads, so

I removed them. Don't forget to flush the brake fluid every two years, or sooner if you're tracking the car once in a

while. Castrol GT LMA is a good quality fluid, especially here in the Virginia humidity.

All the disc rotor vanes and hubs were painted

with a high-temp paint to prevent rust. See this page for info on doing this. The calipers were painted with VHT high gloss and the backing plates were

painted with Rust-Oleum Sliver Stops Rust paint, which keeps the backing plates looking much better as well as giving the

rotors a larger look from a distance. All brake hoses were replaced with high quality stainless steel lines. These brake

lines give the brake pedal a much firmer feel, over the stock rubber brake lines, improving brake modulation feel. The stock

Master Cylinder was retained, it was not replaced with an E32 unit, based on input from others... good input as the pedal

feel and travel distance is fine with the stock E28 Master Cylinder, allowing good modulation of these non ABS brakes.

Here's a link to pictures of a big brake change over, for those who want an idea of what is involved. Lastly, here is a fairly complete

list of BMW brake configurations that will fit the E28. Don't pay any attention to the costs indicated, as they are in Euros, since the list is from a member of the

UK M5 Forum, who lives in Europe.

Update May 11, 2009

Anti-Sway Bar changes

A Suspension

Techniques 22mm (actually 22.2mm) adjustable anti-sway (anti-roll) bar with its red poly bushings, replaced (12/04) the

18.25mm factory anti-sway bar. A 25mm M5 bar with modified brackets was tried, but I found it too harsh and too much more

understeer, given my suspension configuration and the handling feel I was looking for. The stock 14mm rear anti-sway bar was

also replaced with a larger Racing Dynamics adjustable 16mm bar, which is a bit larger than the later model

E28 bar that is 15.5mm. It compensates for the larger front bar I installed which would otherwise increase understeer. The

net effect reduced understeer and improved roll stiffness, without introducing excessive harshness in the cars highway ride.

I feel the car is pretty much dialed in now, handling wise. I tried a number of different diameter anti-sway bars... special thanks

to E28 friends who kindly loaned them to me for my testing, allowing me to find what I was looking for.

Further, you should know that the rear anti-sway bar mounts on the E28 are not really capable

of supporting a larger sway bar, such as an 18mm or larger. Shawn D. has posted info on how to reinforce the rear mounts. Information on how to reinforce the front sway bar mounts for use with a larger 25mm bar has been missing

for a while, but has recently resurfaced in an MS Word format. I have converted it to a ".pdf" format document and it's available

here. Update Nov. 14, 2013 A new bracket support option has been posted to the MyE28.com forum, which can be seen here. It looks to be an ideal solution and you should check it out. A rear support failed just after my 528e was delivered to

its new owner and he is looking into this fix.

Shock Absorber changes

The

shocks were changed August 1994, using Bilstein B6 (HD) models at all four corners, using

Bilstein Application Guide #308 P/N 34-002339 front and 24-006088 rear. They were later revalved for 25% stiffer/faster

rebound control action with the stock springs. Many consider this a very good configuration. In fact, a very recent

comment by Mike Miller in the February 2011 issue of Roundel, TECH TALK, confirms this is still a very good combination, as

he advises here, in 'THE SHOCK ABSORBER CHOICE' comment. You do not want to use the Bilstein B8 (SP) models unless you have installed

after market lowering springs!

UPDATE September 15, 2012

A number of people have asked about recalibrating or tuning

shocks. Here's a short list of articles you may want to read about shocks...

Why Race on Bilstein Shocks? here.

Choosing The Right Shocks here.

Shocks: Solving the Mystery here.

Tuning with Shocks here.

Shock Absorber Tuning here.

Creating Optimal Suspension and Steering Performance here.

And on a related note, but dealing specifically with various spring/shock combinations

for the E28 M5, here are several more links to

discussions on the MyE28.com Forum. The original thread and a later related thread. And a new discussion about staggered wheel/tire arrangements and adjustments thread.

I've

spent about three years borrowing, buying and testing various suspension components and wheel/tire combinations, to arrive

at a configuration I am happy with for my primary use... long distance driving and improved performance in the twisties. However,

you may not like my setup, depending on what you're looking for and the type of driving you do, as sorting out a

vehicles handling is a very personal thing... there are no magic combinations you can simply bolt on! Some good info about

all this is at Turnfast, if you're interested. And some interesting comments about cutting springs

that you might want to read here, since so many people seem to have the physics of doing so backwards.

IMPORTANT NOTE ABOUT SUSPENSION TECHNIQUES REAR ANTI-SWAY

BAR INSTALLATION-

Racing Dynamics no longer markets an adjustable 16mm rear anti-sway

bar, but Suspension Techniques does and it looks like it may actually be the Racing Dynamics part. However, the installation

instructions for tightening the center bolt of the rear link has a major error, as it specifies a bolt tightening torque that

is excessive and will cause a failure! Please see this page which I have modified to show the problem.

Update

Jan. 17, 2008 - E28 Spring Rates, a report by Devinder on MyE28.com has been posted and includes most all of the available springs made for the E28. An excellent resource for you to review,

if you're thinking about changing springs to accomplish a change with your E28 handling response. Check it out!

And

before we leave this info about brake upgrades, you may find the following information very useful...

StopTech Technical White Papers

The Brake Bible

|

| A short rest at Shepherd University, WV, after brake/suspension test runs on back roads |

|

| E39 Style 29 BBS/BMW wheels with hub-centric adapters. |

Update June

11, 2009

(and repeated again Sept. 3, 2010, because some people aren't using this adaptor with

E39 wheels. WRONG!)

E39 Style 29 16x7 ET20 wheels require a 74mm to 72.56mm

hub-centric alloy adapter rings, to make up for the difference in the larger hub bore size of the E39 wheel. The adapter ring

is shown below and is available from the Tire Rack at 1-888-376-8473.

Local E28 owner Marc English advises me that Tire Rack

is now listing this adapter ring as p/n 72.56RING at $3.00 each

It is evidently no longer labeled/stocked as p/n A670

DO

NOT ATTEMPT TO USE THESE WHEELS WITHOUT THIS ADAPTER RING!

And don't forget about the Tire Rack information services documents which cover a multitude

of subjects pertaining to tires and their care right from the start with info about Breaking in your tires.

Sept. 15, 2004

My refurbished wheels came from The Wheel Collision Center. Their quality of work is excellent, as is their level

of service! Wheels are fitted with Yokohama AVS Sport 205/55/ZR16 tires and you can see the E32 big brakes. The larger section

width of the 225/50/ZR16 (9.1 in. vs. 8.4 in.) created a rear wheel fender clearance problem with three people aboard.

Further, I did not want to get involved with "fender rolling" and the lower profile 225/50/16 size created more noise... something

else I was not happy with. The diameter of the 225/50 and the 205/55 are identical, at 24.8 inches, so there are no speedometer

indication differences.

I had previously run Yoko AVS E100 205/60/14 on my

Style C wheels (smaller 23.7 in. diameter) and 205/60/15 on ARE wheels, so I had previous experience with the Yokohama tires.

The 14-inch wheels went to the crusher and the 15-inch ARE's are on a friends 1985 528e.

Why not 17 or 18-inch wheels? As I said above, I tried

several configurations loaned to me, as well as driving quite a few E28s fitted with 17 and 18-inch wheel/tire combinations.

I did not like their feel and what I call 'slugish' performance and high rate of trammeling, due to their large size

and width. Yes, some are very 'pretty', but they didn't deliver the performance I was looking for. My opinion is the

E28 suspension was never designed for anything larger then a 16-inch wheel and while many have involved much larger configurations,

I have never driven one that was clearly superior to my 16-inch configuration, on roads I frequently drive... including back

roads that are driven at a very aggressive rate of travel. I think both Alpina and AC Schnitzer had the right idea, fitting

their E28s with 16x7 wheels and 205/55-16 tires. Think about it.

Update December 23, 2011 -

A good resource for E28 wheel fitment info is Shawn

D.'s "E28 Wheel and Tire Tutorial", which has additional links to other info of this type.

I've added a list I created today, because people keep asking me what wheel/tire combinations are known to fit and

don't have any body contact problems. I used the Tire Rack specs pages for 14" to 17" wheel/tires sizes specified for the 1983-1988 BMW E28. I've personally used or have seen these specific configurations and know they work.

Don't ask me about larger sizes, which won't work unless you're driving an M5, or have had the fender lips rolled or

trimmed. Additional info about tire sizes can be found here, in terms of comparing various sizes. Visit this link for an excellent wheels and tires general information resource.

Also, it's easy to get confused about the different

wheel types and what a specific type looks like. Go here to see a good listing of BMW wheel types. It is a German

language site, but has pictures of all the BMW wheel types, so you can see what a particular type looks like, as well as its

specs.

|

|

|

|

|

|

|

|

|

|

|

The correct type hub-centric Adapter Ring for E39 wheel use on the

E28 -

|

| Hub-centric Adapter Ring |

|

| Front axle hub WITHOUT the Hub-centric adapter ring installed |

|

| Front axle WITH Hub-centric adapter ring installed, ready for E39 wheel |

Newer wheels and tires bring significant handling performance improvements

to the E28. Shown above I am weighing the Style 29 16x7 inch wheel with a new General Exclaim UHP 205/55-16 mounted, compared

to the older TRX wheel with a Michelin 200/60-390mm tire mounted. These tires are replacing the Yokohama AVS Sports which

are now worn after four years of use (11,000 miles). The Exclaim UHP brings with it newer technology and lower cost.

Using an accurate balance beam scale, the new larger 16-inch wheel

and 205/55-16 tire which is 1/4-inch taller, but has a much wider tread width, is nearly one pound lighter, at 38.0 lbs versus

the smaller Michelin TRX wheel and tire assembly at 38.9 lbs. Other tire/wheel combinations are possible, of course, inspite

of the E28s age which still has access to all sorts of combinations to support your specific desires or needs, be it maximum

fuel economy or auto crossing.

The 1983 528e came stock from the factory with the 18-Spoke

Style C 14x6 ET22 wheel (above left), or with the Style C 390mm with the Michelin TRX tires as an option. My 528e was

fitted with the 6 series E24 19-Spoke ET22 390mm wheels (above right) and TRX tires, offered by Evergreen BMW as an option.

Too bad the 19-Spoke was never made in 15 or 16-inch sizes, as it was a very good looking wheel, IMO.

June 8, 2006 Update - (But, not really

the problem!)

Finally found the problem with the front end vibration at 65

MPH. Turns out my Style 29 wheels on the E32 rotors don't like to be tightened over the mid-point torque spec of 74 ft-lbs

± 9 ft-lbs. Absolutely no vibration at any speed when torqued to 70 ft-lbs. (clean threads, lightly oiled)

I had them off just prior to the May 7, 2006 BMWCCA Concours,

to wash the wheel wells and I put them back on at the upper torque limit. We first noticed the vibration on the way to Nottoway

Park and again several weeks ago, before I finally got a chance to locate the problem starting yesterday morning.

Took a day and a half of testing, but this is the problem. Time

was also expended on testing with both the black plastic (1010tire) and aluminum (TireRack) hub centering rings. No difference,

other than the plastic rings require more care in handling and wheel install/removal work, to prevent damage to the plastic

rings.

June 13, 2006 Update - (This is

the real problem!)

Additional tests with three passengers onboard created typical

worn control arm bushing problems, including steering wheel vibration at approximately 52 mph during light brake application.

Replacement parts are on order from Steve Haygood. Parts replacement is shown here.

And a word about tire balancing

-

Unfortunately, our local tire dealers no longer have a highly qualified tire balance

technicians, capable of dealing with the BMW E28 and its very sensitive tire balance needs, to prevent vibration issues. I

had previously involved Tire Van, (link removed 10/6/13) which provided

services to my location, involving the Hunter 9700 Road Force balancing system, but they've gone out of business. I

now use a local area service that has a new Hunter 9700 system. You can reach them here.

2004 Euro headlight installation...

New German lens pattern lamps, buckets and grilles purchased from Till Hansen in Germany.

|

| Stock lights removed, ready for Euro units. |

|

| Euro lights and grilles installed. |

Headlights and grilles installed, ready for new wiring to support use

with high wattage H4 and H1 bulbs. Consultation and power distribution parts came from Daniel Stern Lighting. If you've installed used Euro lamps, they are probably going to have

a milky look from a coating that has accumulated on the inside of the lenses. This is normal because they are not sealed.

Some info on how to clean the inside of the lenses is available here.

Additionally, some excellent information about HID lighting, specifically,

the wisdom of using HID bulbs in place of Halogen bulbs in lamps designed for Halogen bulbs, is discussed here... All about HIDs

|

| 22+ year old headlite connectors. |

The original plan was to connect the existing headlight terminal

connectors to the new relays that would be installed to control the lamps. However, 22+ years had taken its toll on the connectors,

as can be seen above. The connectors were cut off and new connectors were installed to attach to the new relay terminals.

And one of my other vehicles had problems too!

Infact, upon finding that that my 528e headlight socket connectors had become so badily

corroded, I did a quick check of the headlight connectors on my 1988 Chevy K1500 4x4, as I had noticed that their headlights

seemed to be getting dimmer and the horn was barely working... I found their connectors in much worse shape, along with lower

capacity (smaller diameter) wire! After some quick voltage drop tests, it was apparent that the connectors and wiring

needed to be upgraded, as shown below.

The design of the headlight housing is faulty. If you look at it

carefully, you can see that it funnels rain and dirt right into the headlight socket... which I have not used, but instead

used direct bolted connections using all brass hardware, so that the connections remain intact. Installing new sockets would

simply allow the connections to become troublesome, again, as the sockets fill up with dirt and water and corrode again. I

recently looked a neighbors new 2010 Chevy truck... the same undersize wiring exists!

The new relays, power distribution block and fuse was attached to

the truck right front fender inner panel, just behind the battery, allowing good access, as shown below.

If you simply want to replace the corroded connectors, you

can remove these open barrel type connectors with Belden Terminal Extractor Picks, available from NAPA. They are BEL725168 and BEL725169, at $4.69 each.

|

| Using a Terminal Extractor Pick to remove the connector |

The extractor pick is inserted in the small latch groove (above

left) and minipulated to depress the small latch tab on the connector, while pulling on the wire at the rear of the connector

housing to remove the connector. You can see the small latch tab (above right) on the top of the connector, now released and

being removed from the rear of the connector housing.

After a new connector is installed, simply push the connector into

the housing until you hear the little tab snap into its seated position. Properly seated, you should not be able to pull the

wire out of the housing.

|

| Top - Greenlee Kwik Cycle 9 crimper p/n 45504 with a 45509 die. Bottom - Amp crimper |

A few words about terminal crimpers... If you're only doing a few

electrical connections a year, skip this paragraph. If you're involved in extensive wiring or rewiring of a vehicle,

or vehicles, read on...

You will save yourself a lot of trouble and rework, if you use a

good quality crimping tool when doing electrical wiring work on vehicles, involving terminal connectors. Inexpensive crimpers

will work, but don't expect their connections to last as long, or be as trouble free as a terminal crimp made with a quality

tool. The simple stamped crimper tool (bottom) depends on your strength and even then its crimp caracteristics (size, pressure

applied, uniformity, etc.) can not begin to match that of a quality crimping tool (top), with a precision crimping die. All

this translates to a terminals ability to withstand vibration, corrosion, maintain current carrying capacity and other factors

that will determine how well the circuit performs and how long under various conditions.

Having spent over 40 years wiring and rewiring vehicles used

in all sorts of service, I can't overemphisize the value of good terminal crimping tools, if you're doing a lot of this. Here's

a link to an article about crimping terminals, if you're interested.

|

| 12-gauge versus stock wire size. |

The 12-gauge wire shown next to the stock headlight wiring. The

stock wires were fine for the original 35 and 37.5 watt lamps used in the stock 5-3/4 inch 4-headlight configuration. While the

stock wires will work with the Euro 55/60 watt lamps (and many do this) the stock wiring is really not up to the task

as the voltage drop will be about 0.8 volts or more with the Euro H4/H1 lamps. The lamp is only producing 80% of its rated

light output due to this voltage drop! Would you tolerate only getting 80% of your engine's rated horsepower?

The voltage drop when used with 80 to 100 watt H4 and H1 lamps is

unacceptable and this is why the larger 12-gauge wire is required... to say nothing about safety and cooked wires!

A copy of the headlight circuit I devised is available here.

November

23, 2005 Update -

Use Stock Wiring or Larger Gauge Wire?

I have created a separate page addressing the

question of voltage drop and its effect. Click here to go to that page.

|

| Relay sockets mounted on access panel. |

New relays are mounted on the engine side of the right side headlight

access panel, with a brace piece behind the relay screws/nuts. This location does not require any holes be made in the chassis,

inviting potential rust issues in the future. I used BOSCH 0 332 019 151 relays (link updated 8/5/12) with the two output pins (two #87 contacts) rated at 30 amps.

You could also use the Hella H41010001 relay which provides the same circuit. These relays are also available in tab mounting

configuration, which does not require a relay socket... but I prefer the socketed relay type for quick replacement.

|

| Rear of Hella lamps on right side, wires being run. |

June 23, 2006 Update -

Rear view of the right side headlight "Bucket" with the Euro socket

end caps visible. The original headlight connectors are placed out of the way and you can see the new 12-gauge wiring

for high beam, low beam and ground being installed. Power from the side marker light (2 each 18-gauge yellow wire) has been

brought up to the new headlights, to power the small 4 watt city light with the Parking lights turned on.

Keep in mind that the larger lamp (right above) is not wired for

highbeam, only for lowbeam. The third terminal on the socket cap is for the city light connection. Also, on Euro E28 bulb

socket caps, the size of the male tab on the smaller highbeam lamp (left above) is 5/16 of an inch, it is not the standard

1/4 inch tab as used in the U.S. You'll need a mating 5/16 inch connector.

|

| Relay sockets ready for wiring and completed. |

The length of the new wires easily allows the access panel to be

removed and positioned out of the way for headlight aim adjustment or bulb changing. You can see the rubber cap on the righthand

socket cap.

|

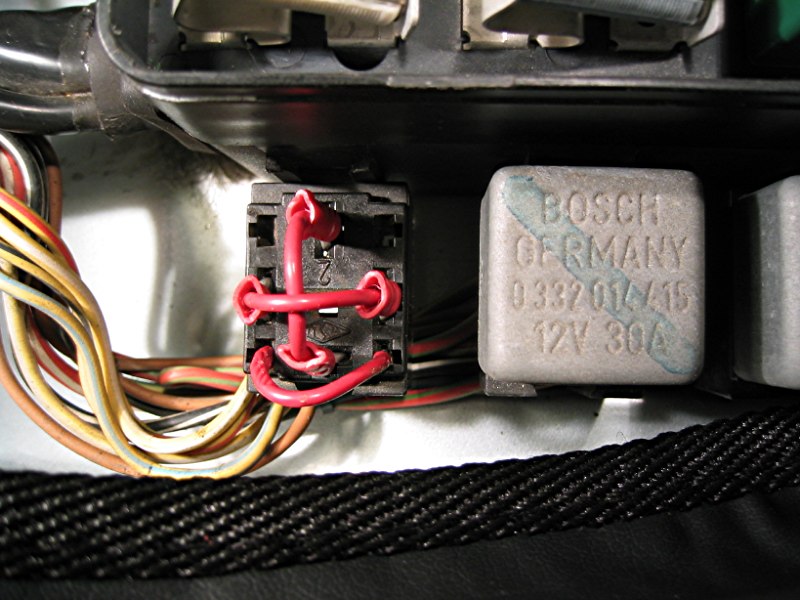

| Check Relay jumpers. |

The Low Beam Check Relay is activated by the current draw of the

original headlight filaments. Since the original headlight relays now only operate the new relays, the Check relay no longer

works correctly and causes the LED on the status panel to illuminate, all the time. This jumper arrangement will correct this

situation.

My jumper

suggestion has been called "hacking at its best" and "nonsensical", along with comparing it to the importance of "removing

the low oil level warning light from the check control panel". An absurd comparison and with no other comment about how else

to deal with a glowing red light on the check control panel. Are you supposed to simply ignore it? Put a piece of black tape

over it? Your general observation skills are so poor that you can't tell if one of your headlights is not working and you

rely on this indicator lamp for such information? Please don't waste my time with such B.S. It only shows your level of ignorance

and adds nothing of value to this web site.

|

| Modified Fuse Box wiring. |

The Fuse panel wiring needs a small modification to allow the Euro

Low beam lamps to remain on, when the high beams are activated. In the picture above, you can see that the wire going from

terminal 85 (white/red) of the Low beam relay has been removed from terminal 87 of the High beam relay and now goes to a butt

connector, along with a brown wire from terminal 85 of the Fog light relay. The brown wire replaced the white/red wire that

also went to terminal 87 of the High beam relay. The other end of the butt connector is tied to ground through a wire-tap

connector.

This change keeps the Low beam on when High beam comes on, just

as late model vehicle headlamps do and also allows use of the fog lights with the low beams. With optional

higher wattage lamps, accurately aimed, I am laying down 360 watts of illumination, driving my dark country roads. Quite an

improvement over the stock feeble 145 watts system from the early 1980's!

|

| Cibie CSR Low and high beam lamps |

Update March 3, 2010

The Cibie CSR E-code 5.75" lampset is no longer be available.

Daniel Stern shared the following with me... < />

====

At 5:36 PM -0500 3/2/10, Consult Daniel Stern Lighting wrote:

Hello, Daniel,

Concerning the two items 82346 and 82348, I inform you that

we no longer make these headlamps, which are obsolete. The production was halted in 2008, and we no longer have the possibility

to furnish them (because) the production facility has been dismantled. Sorry to be unable to satisfy your demand.

Best

regards,

Myriam VAN SIMAEYS

Key Account Manager Aftermarket

====

So, that is that: no more CSRs. Sad news! I now no longer have

any spares for my own car. However, there remains a much-better-than-H4 option for the low beam of the 5.75" round system:

the Hella Bi-Focal H1 unit with city light. Beam plot HERE. It's a little difficult to compare to the CSR plot HERE (which was made on different equipment) but the bulb and voltage are the same. The effective beam width is quite comparable;

the 1800cd line extends from about 25° left to about 25° right. The hot spot is just slightly less intense with the Bi-Focal,

but it is closer to the beam axis, so seeing distance down the road is just about dead-on equal. The Bi-Focal lamp has a metal

reflector, so it'll tolerate overwattage bulbs (which the CSR would not).

The

Bi-Focal optic was co-developed by BMW and Hella and was original equipment (in a model-dedicated mounting setup) on certain

European-spec E30 models and perhaps some others. So I'm not happy the CSRs are gone, but we're not stuck going back to a

pathetic H4 unit (compare the Bi-Focal beam plot to a good quality H4 unit of the same 5.75" size HERE.).

High beams are not problematic; there've always been plenty of excellent high beam options in this size format.

The Cibie convex unit remains the best (and is readily available); the Cibie flat-face unit is definitely no slouch and readily

matches the flat-lens appearance of the Bi-Focal low beam.

I'm about to order in some Bi-Focal low beams out of Germany.

They'll be here in about a month.

Best DS

Improving rear end stop and running light visibility...

A simple project to increase the visibility of the rearend of your

E28 at night, is to install a jumper wire to power the unused inner lamp socket, buy two lamp holder sockets and increase

the candle power of both running lamps by replacing them with type 1003 lamps. Use a type 3497 lamp 45cp (German or

Japan mfg., not U.S. sold "equivalent!) for the stop lights and backup lights. I've tried the Halogen type 796 in place of

the 3497 lamp, yet inspite of its 60cp rating, it didn't look as bright!

|

| Modifications to improve rear end visibility. |

Yellow

or Clear lenses?

Lastly, I've been playing with different lens color configurations for the parking/turn signal and

fog lights. I think I prefer the 'Clear' lenses, which also seem to draw more looks at the front end. The front end also looks

less cluttered with lights, when they're all clear lenses. Yes? The parking/turn signal lamps have yellow bulbs that have

a silvery coating to mask their actual color when used in a lamp with a clear lens. The bulb is available at most auto parts

stores, typically known as 'Stealth Bulbs', 'Chrome Look', 'Silver Vision', etc.

The clear turn signal lenses are available here and also from here. The original factory/dealer installed clear Bosch fog lamp lenses for the E28, P/N 1 305 354 933, are difficult to find.

The last good source I had (Nov. 2011) was here. Please let me know if this link becomes no longer valid.

|

| Yellow versus Clear parking and fog light lenses. |

2004 ECU/DME modification...

September 12, 2007 Update

(because it remains an ongoing issue)

First a comment about chipping...

The M20 eta engine responds extremely well to chipping

IF the engine is in a very good state of tune! I've seen far too many 528e's that have been chipped and results ranged

from no increase to a marginal power increase, because the engine and fuel system needed fixing, involving one or more of

these items:

-Dirty injectors -Weak/leaking FPR -Weak

fuel pump(s)

-Dirty fuel filter -Improper AFM setting

-Incorrect timing belt install

-Bad ECU/DME engine temp sensor -Bad O2

sensor -Bad valve lash

-Vacuum leaks -Bad cat converter -Faulty sparkplugs

-Faulty sparkplug wiring -Worn distributor cap/rotor -Bad grounds

-Bad electrical connections to these items, creating random issues

(includes fuse connectors, relays and relay pin and socket contacts)

Too many of these issues exist with 528e's because they

weren't really properly maintained or tuned, which I've personally observed and worked on over the past 20+ years.

And I've seen some BIG SIX M30 systems that weren't any better, either. I can't over emphasize this point.

DO NOT WASTE YOUR MONEY ON A

PERFORMANCE CHIP

IF THE REST OF THE SYSTEMS ARE

NOT IN PEAK TUNE!

|

| "027" DME/ECU with EPROM socket to allow "chiping". |

Update December 12, 2012 -

The question about the cost of a chip versus what it provides in

terms of a power increase, continues to be a popular, but stupid question, if you simply do the math. The E.A.T. chip I purchased,

produces a 15.8 RWHP (as tested on a dyno) power increase. The $200 cost divided by 15.8 RWHP it produces shows us that the cost per HP gained is only $12.66 per HP!

If you can show me a lower cost modification that results in more HP, please tell me what it is. I have built and helped build

over 300 competition engines, over the past 50 years and I've yet to see such cheap HP per dollar modification gains,

like a well designed 'chip' produces.

And lastly with respect to Dyno test result numbers and why they vary between different Dyno

manufactures, (for those of you who wrote and asked) I suggest you read these two articles, here and the other one here. I would hope that understanding the points being made in these commentaries, will assist in preventing stupid arguments

about who's dyno is correct and who's isn't. A waste of good time, otherwise spent on your E28 projects.

Update July 17, 2009 -

(updated E.A.T. Product#)

A used DME/ECU from a 1987 325e, with a BOSCH green label part#

0 261 200 027 (used in '84/'85 -'87 325e and 528e) has been installed to support chip swapping, as it has an EPROM

socket which the earlier 1983 "007" (last 3 digits) DME/ECU does not have. It used four (4) chips soldered in place

and is not easily removable. A Mark D'Sylva E.A.T. performance chip, product# E30-027.5K5 is being used in the "027" DME/ECU. Other chip makers such as Conforti, Dinan

and others who make a chip for the M20 eta engine, also require this model DME/ECU.

Update Nov. 1, 2007 -

If you'd like to know more about your Bosch Fuel Injection and Engine Management systems, get a copy of

the Charles O. Probst book, published by Bentley. A quick review of Chip Tuning Fundamentals may be helpful, too.

A second used "027" DME/ECU was purchased from Ebay, ($45.)

April 2005, and the rear of the glove box was modified to allow the second ECU to fit below the original ECU mounting position.

The second unit is being used to test other chip brands and revised chips from Mark D'Sylva, by quickly switching between

the two ECU's. NOTE - The second and third ECU's are fitted with ground straps, attached to the original

ECU located in its normal mounted position, at the top of the glove compartment. Do not swap cables

on ECU's when they are not properly grounded!

NOTE - The screws in the ECU look like Phillips

head #2, but they are really POZIDRIV #2, which is different. A Phillips will work, but be careful as the Phillips can rotate

out of the screw head and damage it.

|

| Inside the DME/ECU |

Open the top of the DME/ECU (see the position of the mounting tabs)

and swing it open like a book, which is how it's positioned above. There is a rubber cone shaped spacer, that you have to

remove off of its grooved plastic pin, then you can swing the circuit board up and to the right, as it hinges on the connecting

wires. You can see the chip socket with its factory chip still installed. Remove the chip carefully and replace with the new

chip of your choice, being very careful not to bend the chip's pins as you place them in the socket.

|

| Close-up of factory chip in its socket |

This close-up of the chip socket shows that it is labeled as "S712"

on the circuit board. It is a 24-pin chip socket. The chip has a detent or notch on one end to identify proper position in

the socket, which also has a detent or notch, or a picture of one on the circuit board next to the chip socket. Make sure

you position the chip correctly.

November 2009 - An important note

The availability of 24 and 28-pin EPROMs which are used by chip programmers, such as E.A.T.,

have become quite difficult to obtain, since they are no longer manufactured. Don't be surprised if you have difficulty obtaining

performance chips in the future, for use in these vintage ECU/DMEs in your BMW E28.

Easiest way to insert the chip is to line-up all the pins on one

side and start them into the socket holes, about 1/8 of an inch. Then, while maintaining pressure on the chip, move it toward

the socket holes that already have the chip pins partially inserted and line-up the pins with the socket holes on the other

side. Once aligned, lower that side down toward the socket holes being careful to insure that all pins are entering the sockets

and not bending. When all the pins have started into their respective sockets, slowly push the chip down and seat all pins

in their sockets.

There have been many reports about ECU problems associated with

failed circuit trace and power transistor solder connections, mostly on the later 535 and M5 ECUs, but I haven't seen any

"027" ECUs with this problem. However, while it's open, it's a good idea to take some time to look at yours for such potential

problems. Here is a link to another web page that discusses making repairs to transistor solder connections, give it a look.

Lastly, clean the ECU plug on the cable and its connector on the

ECU with a good quality contact cleaner, such as a CAIG product. Also clean the cable and connector on the Idle Control Module, while you are in the area. Follow what ever instructions

came with the chip and enjoy.

What level of performance improvement are you likely to obtain?

Well, I have been testing the Mark D'Sylva E.A.T. chip since early February of this year (2005), along with several other

brand performance chips and this is what I experienced:

- Clearly apparent increase in horsepower starting above 3,200

to 4000 rpm, depending on which brand chip is involved.

- Increase in redline to approximately 5300 rpm, over stock 4750

rpm gives additional speed in gears, with all chips tested.

- Excellent performance increase for the dollars spent.

-

Copy of 3/31/05 State emissions tests (below) shows

that the E.A.T. chip (installed at time of tests) had no adverse effect on Virginia emissions test parameters.

-

April 23, 2005 update

- The timing belt was found to be retarded by one tooth (see Maintenance Tips Pg. 1) and after correction with a new belt installation, performance was further

improved. Additionally, the Fuel Pressure Regulator was found to be faulty, creating an intermittent/random engine power loss

during full throttle operation. Another used "027" DME/ECU unit was purchased through Ebay, for installation of other

brand performance chips, for testing against each other. This ECU cost $19.99!

-

May 25, 2005 update

- A used Dinan 528e chip (D900-2711) was purchased and I have completed 300+ miles of testing with it. This particular

Dinan chip is very peaky, compared to the D'Sylva E.A.T. chip. The Dinan doesn't seem to have much below 4k RPM and then it

comes to life rather abruptly. The D'Sylva chip starts delivering increased power about 3200 RPM and continues to increase

power right up to the rev limit. Its power band is much broader, where most of our driving is done.

-

July 30, 2005 Update

- A used Jim Conforti 528e (027-000) Turner Motorsport Performance Chip was received, on loan from a BMW friend

(thank you Paul Benson!). Its performance is much like the E.A.T. chip, but a little weaker at mid-rpm, while feeling a bit

stronger as maximum rpm is reached. This Conforti has a broader band of top end power, unlike the Dinan with its very

narrow power band. Still, the E.A.T. chip offers more power at mid-rpm where most of our driving is done. It is the best of

the three, given its good mid-rpm power, in my opinion.

All tests were run on the same two country roads near the

Shenandoah River, that I've traveled for over 22 years, testing suspension setups, tires, lighting, etc. Test sections

were three miles each way, with each chip involved by simply pulling over, shuting off the engine, swapping the ECU cable

between units placed in the bottom of the glove compartment, restarting and running the section roundtrip with that ECU/chip

combination. Swapping ECU's took about 10 seconds, once I got a feel for it. A minimum of six rountrip runs were made during

each test session and a total of 75 runs were made over a period of 4 months. The chips were also moved between the three

different ECU's, but no difference was noted, except during their startup and learning period of about 20 seconds. Some fuel

mileage checks were made, but are not considered typical due to the "pushed" driving during these tests.

Lastly, several cruise control runs were made

using a long, moderatly steep grade road, that can not be completed in 5th gear at 55 mph with the stock ECU. Only the

E.A.T. chip with its better mid-rpm power was able to make the grade via cruise control. The other chips could not pull

the grade, just as the stock chip couldn't. Another benefit of the E.A.T. chip.

August 14, 2005

Update - To help quantify the power increase for you, with an example easily understood, I would indicate

that an additional person in the car (~175lbs) on this up hill grade, results in the vehicle just barely starting to slow

down as it reaches the top. With the stock chip and an additional person onboard, downshifting to 4th gear would have been

necessary after the first third of the way up the hill, in order to maintain velocity. An earlier downshift is necessary,

if the air conditioning is running... also necessary with the E.A.T. chip with an additional person and the air running, requires

a downshift at the half-way point to maintain velocity.

November 7, 2005 Update - A used 1988 528e (known as the Super eta) Tachometer face

plate was installed to have the Tach register the true redline of the E.A.T. chip. Pushing the needle well into the red of

the original Tach face 4750 RPM redline, to the new 5200 RPM redline is something I couldn't do. Too many years of racing

expensive engines where exceeding the redline can result in serious engine damage.

Dyno Results -

During the summer

of 2006 I made two Dyno runs at York Automotive to see what the E.A.T. chip was actually producing in terms of RWHP (Rear

Wheel Horse Power) over that of my stock configuration. With a fresh tune, the runs averaged:

106.5 RWHP with stock chip and ECU (008)

122.3 RWHP with E.A.T. chip in

"027" ECU

For those of you who look at the total cost of any modification you make to

an engine, in terms of cost per RWHP gained, the E.A.T. chip is the the most cost effective method to increase engine horsepower.

In my case it resulted in a cost of $12.66 per HP ($200/15.8 RWHP=$12.66) gained! If you have more cost effective methods

to gain horsepower, including dyno test results documentation, I'd sure like to hear about them and see your documentation.

|

| 1988 Super "eta" Tachometer face plate with higher 5200 RPM redline. |

April 17, 2007 Update

- The 528e had her last Virginia emissions inspection today, as she'll be 25 years old when the

next registration renewal is due and will not be required to have an emissions inspection. It's interesting to note that this

last inspection was so clean, that the equipment was checked and tests run again. Not the first time this has happened, but

at 25 years old, with the original catalytic converter still in use and a non-BMW ECU/DME chip installed (E.A.T.) it shows

what the longevity of a 528e can be, given proper longterm care and consistant maintenance. The numbers and her performance

says it all.

|

| Copy of emmisions test results with E.A.T. chip installed. |

Major Engine Modifications -

If you want to make major engine performance modifications,

I strongly suggest that you consult the folks at Metric Mechanic, who specialize in providing high performance BMW engines and drive trains.

I have driven an E28 (528e) with one of their M20 "Sport i Engine" configurations, delivering 205 HP and it is a very nice

configuration. Metric Mechanic has a great reputation and it certainly beats running around and trying to find an experienced

local BMW engine builder to do the same thing. I am not knocking my "e to i" friends, but their time and money produced less

powerful engines, with some things still not fully sorted, compared to the MM engine I experienced.

The best info on the subject I've found is on Fred Kim's strictlyeta web page, dealing with his work on his E30. A good resource.

Lastly, I currently have a Metric Mechanic HiFlo ST cylinder head that I am installing on my

M20 engine and this project is documented here.

- Installing a front strut brace and modifications required.

HOME

Maintenance Tips

Rod's autos and racing in the earlier years.

|

|

|

|